HY-DTS5100 series distributed optical fiber temperature measurement system is designed with Ramam scattering which is sensitive to temperature and only sensitive to temperature. Its positioning accuracy, spatial resolution, temperature accuracy and other technical parameters all meet the requirements of engineering applications.

1. Introduction to the system

HY-DTS5100 series distributed optical fiber temperature measurement system is designed with Ramam scattering which is sensitive to temperature and only sensitive to temperature. Its positioning accuracy, spatial resolution, temperature accuracy and other technical parameters all meet the requirements of engineering applications.

This analyzer requires the use of multi-mode fiber optic cables and a loose tube fiber optic cable structure.

Distributed optical fiber temperature measurement host is a new generation of optical fiber temperature measurement host developed based on fiber optics, optoelectronics, small signal processing technology, high-speed signal acquisition and processing technology. It adopts embedded software and hardware system, which has the advantages of stable system, compact structure and low power consumption. It adopts optical fiber sensing technology, which is free from electromagnetic interference, intrinsically safe, and has a long service life. It can operate in various harsh environments.

Imported lasers and optical devices are used internally, optical circuits, electronic circuits and reliable control software are formed through integrated circuit modules, and are completed through strict production, assembly and product tests. The product has the advantages of high efficiency, low power consumption, high stability, convenient use and maintenance, and long life. It is widely used in optical communication, optical sensing and other related fields.

Features

Real-time online monitoring; high temperature measurement accuracy; long-distance distributed measurement; 24-hour continuous monitoring; multiple alarm methods; intrinsic explosion-proof.

application

On-line temperature monitoring of power cables; temperature monitoring in the field of transportation; temperature monitoring in oil depots, arsenals, dangerous goods depots, grain depots, cold storage and other warehouses; petroleum and natural gas industries.

Distributed optical fiber sensing principle: the interaction of laser and optical fiber material molecules produces scattered light.

1. Rayleigh scattering: not sensitive to temperature;

2. Raman scattering: temperature sensitive;

3. Brillouin scattering: sensitive to stress and temperature.

Principle of fiber grating sensing:

1. Using wavelength division multiplexing technology, 40 sensors can be connected in series on an optical fiber;

2. Using a specific package, it can measure the temperature, strain and other parameters on the optical fiber at the same time.

Practical application in cable trench/substation

Temperature monitoring:

Fire Monitoring of Cable Tunnel of Beijing Shougang Corporation

Temperature monitoring of power cables in Yangzi Petrochemical Olefins Plant

Temperature Monitoring of Power Cable of Shanghai Jinshan Petrochemical Company

Fire Monitoring in the Cable Tunnel of Shandong Jinan Iron and Steel Company

Fire Monitoring of Cable Corridor of Shanghai Tunnel Company Project

Fire Monitoring in the Cable Tunnel of Nanjing Iron and Steel Group Company

The temperature measurement project of the national grid cable tunnel in Xi'an Xixian New District

Huaneng Fujian Changle Power Plant Distributed Optical Fiber Temperature Measurement Project

Huaneng Haimen Power Plant Optical Fiber Grating and Distributed Optical Fiber Temperature Measurement System Project

Wuhu Power Plant Distributed Optical Fiber Temperature Measurement Project

Ningxia Shenmei Distributed Optical Fiber Temperature Measurement Project

Meixian Heshuyuan Power Plant Fiber Bragg Grating and Distributed Fiber Optic Temperature Measurement System Project

Fiber Bragg Grating Temperature Measurement Project of Jiangmen Power Supply Bureau Qiaotou Substation

Jiangmen Power Supply Bureau Dusoft Substation Distributed Optical Fiber Temperature Measurement System Project

Shaogang Fiber Bragg Grating Online Temperature Monitoring System Project

Fiber Bragg Grating Online Temperature Monitoring System Project of Zunyi Power Supply Bureau

Fiber Bragg Grating Online Temperature Monitoring System Project of Guizhou Power Supply Bureau

Xiangshan Power Supply Bureau Fiber Bragg Grating Online Temperature Monitoring System Project

Nanning Power Supply Bureau Fiber Bragg Grating Online Temperature Monitoring System Project

Changle Power Supply Bureau Fiber Bragg Grating Online Temperature Detection System Project

2. Technical standards

The equipment provided by our company is designed, manufactured, inspected and installed in accordance with the following standards and regulations. Ensure that the standard used is the latest version. If the content of these standards is inconsistent, the terms of the highest standard shall be implemented or the standards agreed upon by both parties shall be implemented. The following standards and specifications are part of compliance, but not all of them.

GB/T 2423.1-2008 | Environmental testing of electrical and electronic products |

GB 4943-2001 | Information technology equipment safety |

GB/T 17626.6-1998 | Electromagnetic compatibility test and measurement technology Radio frequency field induced conducted disturbance immunity |

GB/T 17626.11-2008 | Electromagnetic compatibility test and measurement technology Voltage sag, short-term interruption and voltage change immunity test |

GB/T 21197-2007 | Linear optical fiber temperature sensing fire detector |

3. System equipment

3.1 Temperature measurement host parameters

Detection distance | 2Km, 4Km, 6Km, 8Km, 10Km, 12Km 16Km (manual: 2~30) |

Number of detection channels | 1~16 (expandable) (source: manual) |

Temperature range | -10~250℃ (High temperature measurement can reach 350℃, need to cooperate with special optical cable application) (Manual: -50~350) |

Temperature resolution | 0.1℃ |

Temperature measurement accuracy | ±0.5℃ |

measure time | 5s (manual: <3; single channel, 2km) |

Spatial resolution | 1 meter |

positioning accuracy | 1 meter (manual: ±1) |

Communication Interface | LAN /RS232/RS485 |

power supply | 18~28V, 12W avg, 14 max (manual: 220V±10%) |

Machine box | 390mm(W)×305mm(D)×68mm(H) |

weight | 3 KG |

Operating temperature | -10℃~50℃ (Manual: -20~+45) |

Storage temperature | -40℃~70℃ |

Relative humidity | ≤95%RH(40±2℃) |

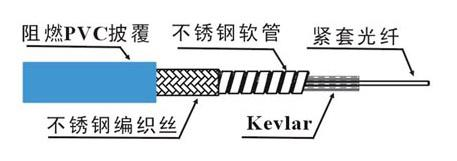

3.2 Selection of temperature-sensitive optical cable

The temperature-sensing optical cable uses 50/125µm multi-mode optical fiber in the inner core, Kevlar sleeve is outside the inner core, and the outer sleeve is protected by armor (stainless steel hose and stainless steel braided wire), and the outer sleeve is made of flame-retardant low-halogen PVC material, as shown in the figure below Show. The entire optical cable structure ensures that the temperature-sensitive optical cable has a faster temperature response speed, strong tensile and compression resistance, high temperature resistance, and flame retardant capabilities, and can adapt to harsh construction conditions and working environments.

Figure 1.2 Schematic diagram of the cross-section of the temperature-sensitive optical cable

The main technical indicators are as follows:

Product number | RTS-100 |

Application area | Temperature monitoring |

Temperature range | -10℃~+150℃ |

Connector type | E2000/APC |

Core diameter | 50/125μm |

Working bandwidth | Greater than 1000MHz @ 1310nm |

Compressive strength | 300N/5cm |

tensile strength | 200N |

life | >30 years |

Protection level | IP67 |

3.3 Fiber access

This system adopts imported E2000/APC connector, which has a special spring gate design, which can protect the pins from dust and wear. When the connector is pulled out, the gate will automatically close to prevent laser damage.

The E2000 connector is easy to install and has a push-pull locking setting. When it is fully inserted, you will hear a "click", which is good for different operators.

Figure 1.3 E2000 optical fiber connector

3.4 Fiber Maintenance

The optical fiber is made of silica, which is a precision optical component. The light-transmitting part is only tens of micrometers. Therefore, it is necessary to keep the end face clean. When maintaining the end face of the optical fiber, please follow the precautions below.

(1) You can use a dedicated fiber end face cleaner, absolute ethanol, absorbent cotton or dust-free paper, etc. to clean the end face;

(2) During the cleaning process, pay attention to control strength to avoid hard objects scratching the end surface;

(3) Every time you clean, you must wipe it off. Do not wipe repeatedly to avoid secondary pollution and scratching of the end surface;

(4) Each cleaning paper can only be used once to avoid secondary pollution.

Figure 1.4 Fiber end face maintenance

3.5 Fiber optic cable splicing and host access

The optical fiber temperature measurement system measures the temperature by measuring the intensity of the optical fiber scattered signal, so the optical cable connection method is related to the accuracy and accuracy of the temperature measurement, so we make the following requirements:

(1) No movable joints are allowed in the temperature measurement optical cable link: the movable joints are affected by dust, humidity, and the subjective judgment of the construction personnel's connection reliability, which will affect the connection quality, and then affect the temperature measurement effect;

(2) Control the number of optical fiber fusion splices: It is required that the construction minimize the fusion splices and reduce the loss, and the total should not exceed 1dB, that is, within 10 points;

(3) Fiber splicing quality: Since the system only has echo signals, splicing loss is a two-way effect, and the single-point loss is controlled within 0.1dB;

(4) Host access of optical cable: use fusion splicing method, and add optical cable splice box to protect it, and place it in the cabinet. Lightning affects equipment operation.

Figure 1.5 Sealed optical cable splice box

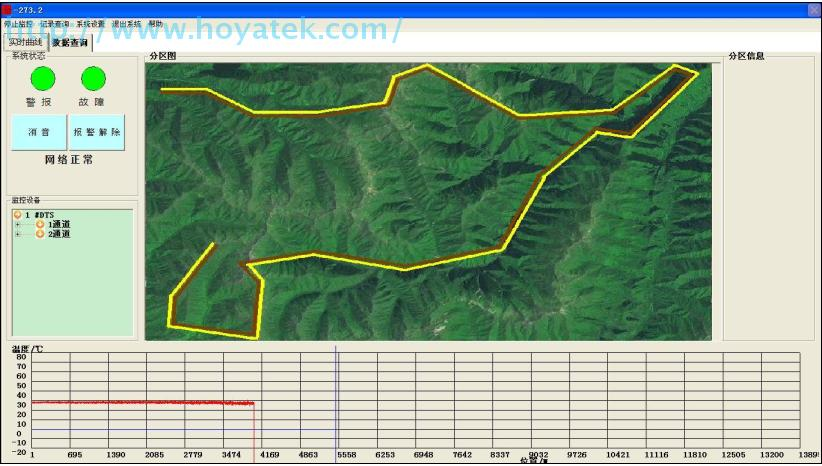

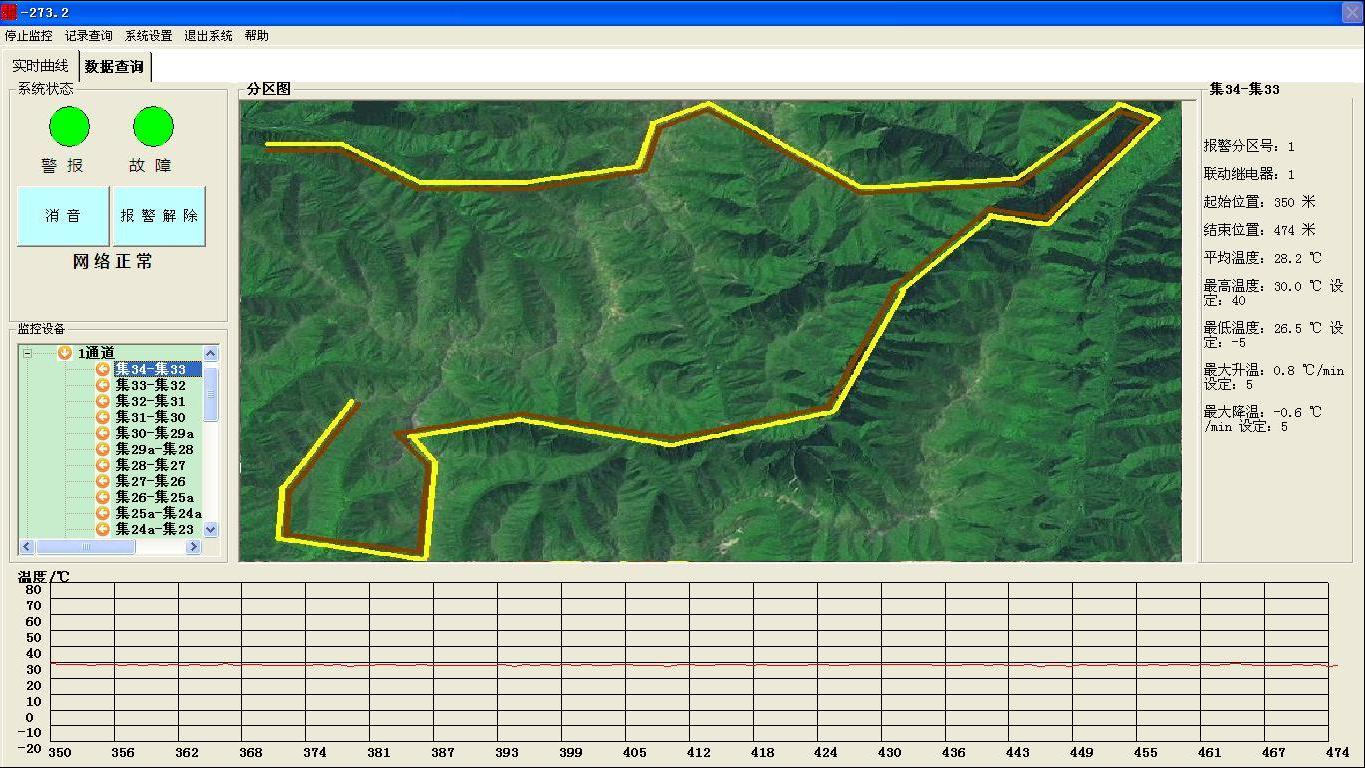

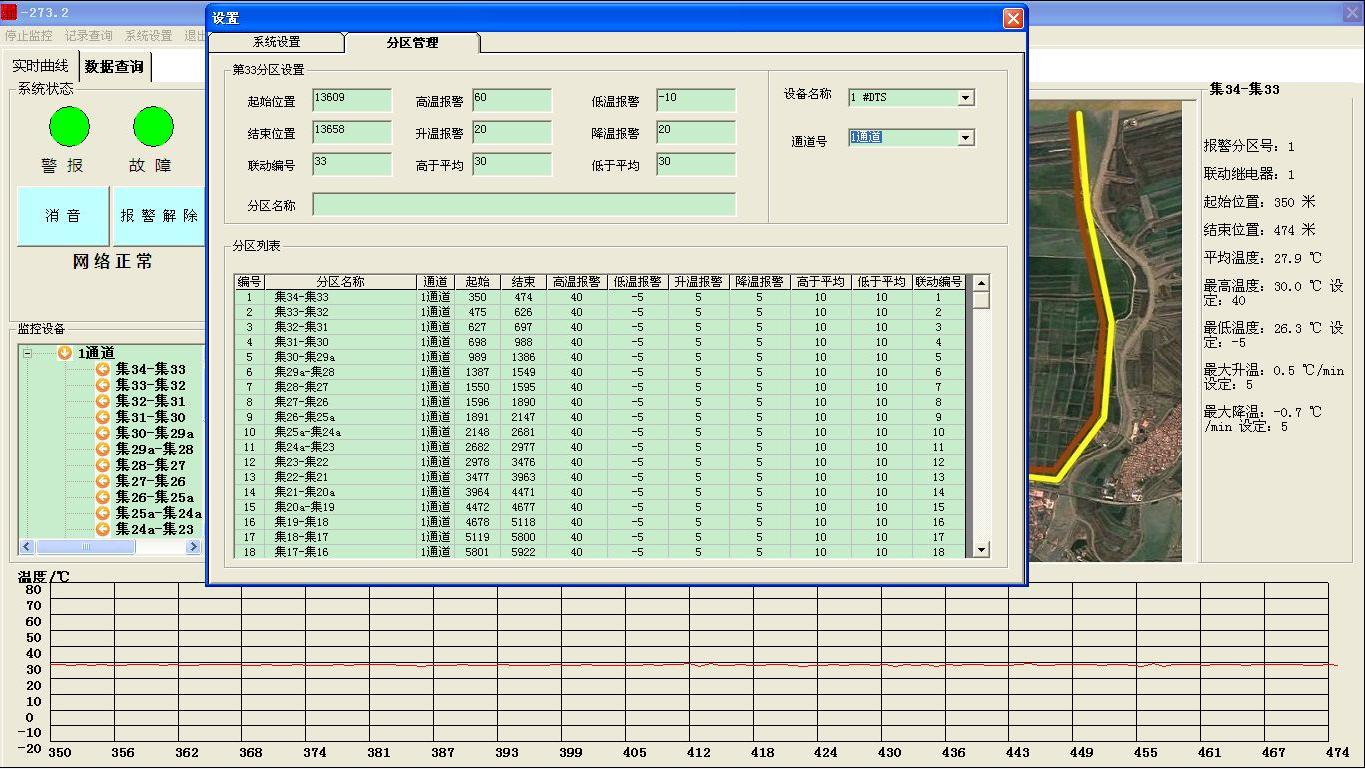

4. Distributed optical fiber temperature measurement and monitoring software interface

4.1 Main interface

(Display area route map; partition)

A. Channel zone display

B. Partition management

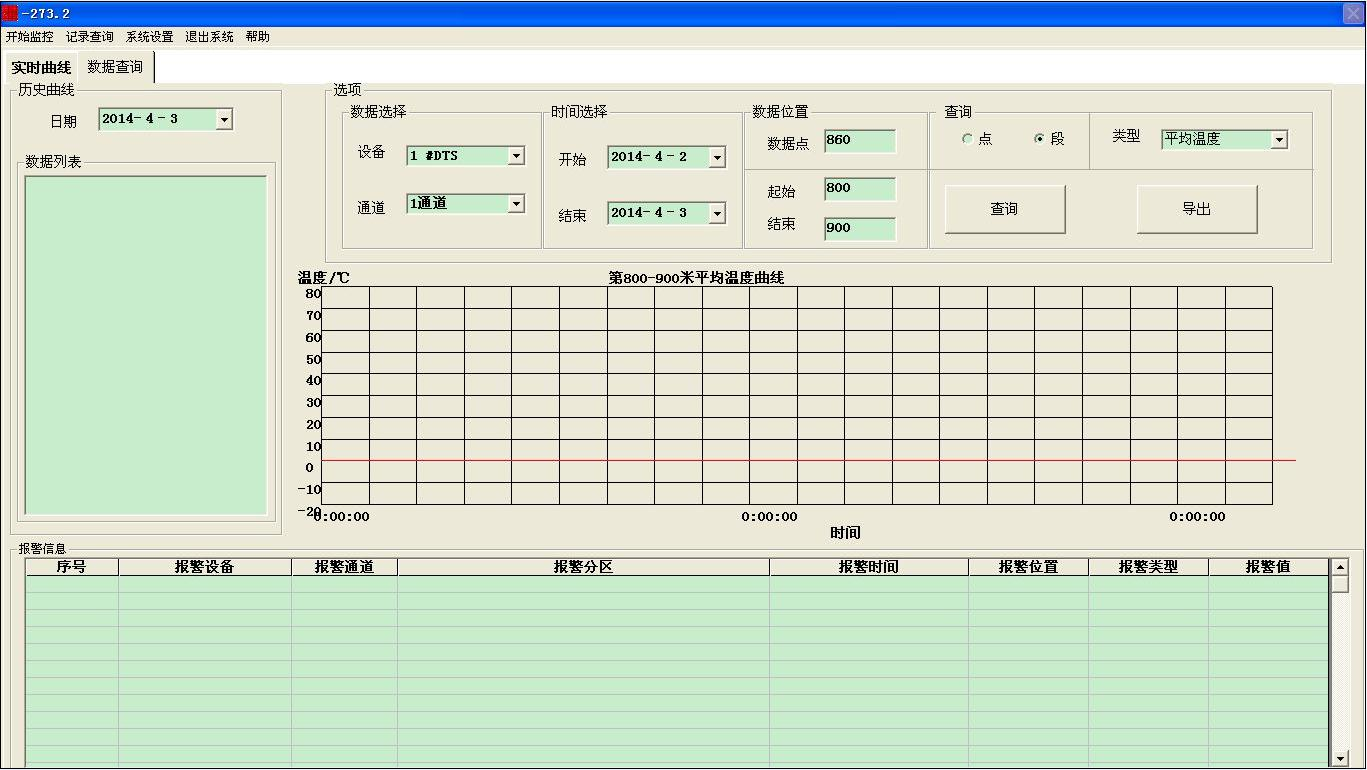

4.2 Data query

4.3 Historical alarm

Temperature measurement host parameters

Detection distance | 2Km 、 4Km 、 6Km 、 8Km 、 10Km 、 12Km 16Km |

Number of detection channels | 1~16 (expandable) |

Temperature range | -10~250℃ (High temperature measurement can reach 350℃, need to cooperate with special optical cable application) |

Temperature resolution | 0.1℃ |

Temperature measurement accuracy | ±0.5℃ |

measure time | 5s |

Spatial resolution | 1 meter |

positioning accuracy | 1 meter |

Communication Interface | LAN /RS232/RS485 |

power supply | 18~28V, 12W avg, 14 max |

Machine box | 390mm(W)×305mm(D)×68mm(H) |

weight | 3 KG |

Operating temperature | -10℃~50℃ |

Storage temperature | -40℃~70℃ |

Relative humidity | ≤95%RH(40±2℃) |

0755-89217387