Back to top

Time:2021-10-13 Preview:957

Power Industry - Distributed Optical Fiber Temperature Monitoring System Application Technology Solution

1. Necessity of temperature monitoring in the power industry

With the development of my country's economy, the power system is developing towards high voltage, large power grid, large capacity and automation. Once an accident occurs, it will cause huge losses to the national economy. How to conduct online monitoring of the running power equipment and conduct safety prediction and temperature change trend analysis, how to conduct scientific analysis of equipment quality, operating environment, operating mode, equipment aging, load imbalance, etc. through real-time data, these are urgent problems that need to be solved in the power system. Traditional infrared thermometers, infrared imagers, temperature sensing cables, thermal resistance temperature measurement systems, etc. can only measure the temperature of local positions in the power system, and cannot provide a scientific basis for safe, economical operation and efficient monitoring. "Linear fiber optic temperature sensing fire detection system" is a new mature product for fire detection and alarm. The detector of the fiber optic sensing system is a special armored optical cable. It senses and transmits information through laser signals. The intrinsic safety, insulation and explosion-proof characteristics of the optical fiber can be widely used in the power industry system. The fire alarm system composed of it can monitor the fire hazards of cable tunnels, cable trenches, transformers, switch cabinets, cables and other parts of the enterprise in real time. Haoyuan DTS distributed optical fiber temperature monitoring system can be used for safety monitoring of cable body temperature, cable ambient temperature, high-voltage switchgear, transformer contact temperature, etc. in the power industry.

2. The significance of temperature measurement in the power industry

[Improve safety assurance]: Real-time temperature monitoring of the operating status of power industry equipment can timely and effectively understand the on-site status and prevent accidents before they happen;

[Reduce labor costs]: The system can achieve 24-hour real-time monitoring, which can save manual inspections, solve the difficulties of difficult-to-monitor locations, and fill in the blind spots of monitoring; if an abnormal temperature alarm occurs, it can effectively locate the alarm and guide the staff to perform positioning maintenance, saving time and improving maintenance efficiency;

[Ensure economic benefits]: The system can achieve early warning and achieve the goal of "unmanned substation", which can effectively avoid safety hazards and safety accidents, thereby ensuring safety while also ensuring economic benefits;

3. Application of Haoyuan DTS Distributed Optical Fiber Temperature Measurement System

This system uses today's advanced optoelectronic technology, communication technology, microprocessor technology, digital temperature sensor technology and original low temperature, strong electric field and humid environment operation technology. It can monitor the temperature in different environments, detect potential accidents early and minimize losses. At the same time, it can also provide a large amount of online monitoring data, providing a reliable basis for operators to fully understand the operation of power equipment.

[Advancedness]: Based on the distributed optical fiber temperature measurement technology that is widely promoted in the international power industry, and based on the successful application experience of nearly 20 years abroad, this system has excellent technical performance and quality;

[Safety]: Optical fiber is used as the medium for temperature sensing and signal transmission. The sensor does not need power supply to work, is inherently safe, has excellent insulation performance and anti-electromagnetic interference, and the sensor installation meets safety regulations;

[Stability and Accuracy]: Temperature data is obtained by detecting the movement of light wavelength. The sensor is only sensitive to temperature, avoiding the problem that traditional sensors are easily affected by interference factors such as power supply fluctuations and transmission line losses. The system is stable and reliable; the temperature measurement accuracy reaches ± 1℃, the temperature resolution reaches 0.1℃;

[Long-term operation with high reliability]: The system runs safely and reliably, with stable performance, suitable for long-term continuous operation in harsh environments;

[Compatibility]: The monitoring host has its own standard communication interface, providing Ethernet port, RS232, USB, etc., combined with the integrated automation system of the variable power station, to achieve data sharing, simple management, and seamless connection with related systems;

[Economical]: The system cost is economical and reasonable, with high cost performance. After it is built and put into use, it can work unattended for a long time, with low maintenance cost;

[Ease of operation and maintenance]: The human-machine interface is friendly and easy to operate; the sensor has no zero drift, no need to calibrate again, and the system is maintenance-free;

4. Single system solution design

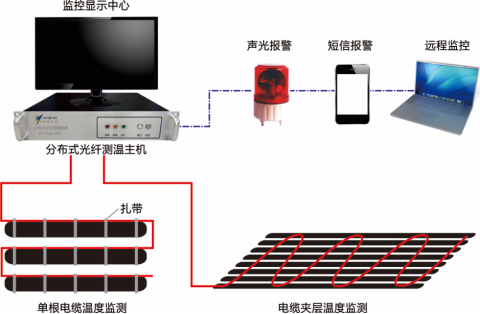

4.1 Design of cable body temperature monitoring solution

Cable body temperature monitoring can be divided into single cable temperature monitoring and cable interlayer temperature monitoring.

Ø Automatic real-time detection: 24-hour real-time online monitoring of cable temperature changes. When abnormal temperature occurs at one or more points on the cable, the system can immediately locate and alarm.

Ø Network linkage: When an abnormal temperature alarm occurs, the sound and light alarm and SMS alarm functions can be linked. The system can send the alarm information to the operator's mobile phone. At the same time, the on-site alarm status can be viewed through computer remote monitoring.

4.2 Design of environmental temperature monitoring scheme for cable trenches and cable tunnels

Ø Automatic real-time detection: 24-hour real-time online monitoring of the overall temperature changes of the cable trench or cable tunnel. When abnormal temperature occurs at one or more points in the monitoring environment, the system can immediately locate and alarm.

Ø Network linkage: When an abnormal temperature alarm occurs, the sound and light alarm and SMS alarm functions can be linked. The system can send the alarm information to the operator's mobile phone. At the same time, the on-site alarm status can be viewed through computer remote monitoring.

4.3 Design of high-voltage switchgear temperature monitoring scheme

Ø Automatic real-time detection: 24-hour real-time online monitoring of the temperature changes of the high-voltage switch cabinet contacts. When a certain contact or multiple contacts of the high-voltage switch cabinet have abnormal temperatures, the system can immediately locate and alarm.

Ø Network linkage: When an abnormal temperature alarm occurs, the sound and light alarm and SMS alarm functions can be linked. The system can send the alarm information to the operator's mobile phone. At the same time, the on-site alarm status can be viewed through computer remote monitoring.

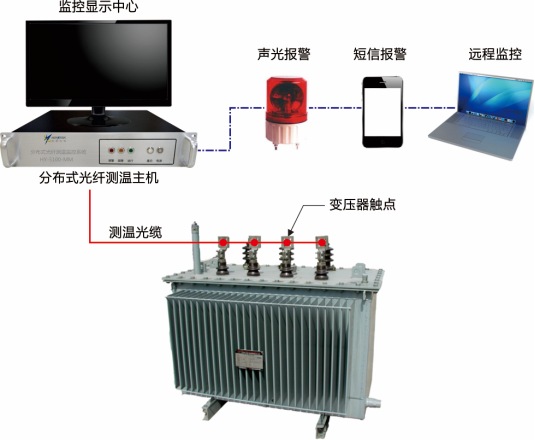

4.4 Design and implementation of transformer temperature monitoring scheme

Ø Automatic real-time detection: 24-hour real-time online monitoring of the temperature changes of the transformer contacts. When one or more contacts of the transformer have abnormal temperatures, the system can immediately locate and alarm.

Ø Network linkage: When an abnormal temperature alarm occurs, the sound and light alarm and SMS alarm functions can be linked. The system can send the alarm information to the operator's mobile phone. At the same time, the on-site alarm status can be viewed through computer remote monitoring.

5. Related Case Studies

0755-89217397