Back to top

Time:2021-10-13 Preview:957

(1) Distributed optical fiber pipeline anti-theft and leakage detection device for oil and gas pipelines (anti-excavation and leakage);

· Application Background

As an important means of energy transportation, oil and gas pipelines have many advantages such as continuous transportation, high efficiency, large transportation volume and low cost. They are the fastest, safest, economical and reliable way to continuously transport large amounts of oil, and have become an important link in the development of the energy industry.

Pipeline facilities require huge investment and are relatively hidden in space. They may be damaged due to unintentional human factors. The leakage of flammable and explosive substances will bring great safety hazards. In recent years, drilling and oil theft have occurred frequently, causing huge economic losses and environmental pollution. Construction excavation and geological disasters can also cause pipeline ruptures. Oil and gas pipeline leakage accidents continue to occur, causing very large economic losses, which may cause combustion and explosion, or cause large-scale leakage of harmful and toxic substances to pollute the environment and cause casualties.

System composition:

1. The oil and gas pipeline integrated online monitoring system uses a distributed optical fiber pipeline anti-theft monitoring system and a distributed optical fiber pipeline leakage detection system.

2. Use two of the redundant communication optical cables in the oil and gas pipeline, one to the vibration system and one to the temperature measurement system to monitor the temperature distribution and vibration distribution of the oil and gas pipeline respectively.

3. The temperature measurement system and the vibration system are connected to the data server via Ethernet for comprehensive analysis and processing and early warning alarm.

System functions:

1. Use a distributed optical fiber temperature measurement and leakage monitoring system to monitor the temperature distribution of oil and gas pipelines in real time. When the oil and gas pipeline leaks, the system can sense the temperature changes nearby and alarm.

2. Use a distributed optical fiber vibration monitoring system to monitor the pipeline environment in real time to prevent pipeline rupture and leakage caused by human construction.

3. Unattended security monitoring can be achieved, and project targets can be monitored through remote desktop display and SMS alarms.

4. It can be linked with other equipment, such as sound and light alarms, video cameras, etc.

(2) Distributed optical fiber pipeline anti-theft monitoring system for oil and gas pipelines (anti-excavation);

The transportation of oil and natural gas is closely related to the national economy and people's lives. Compared with road transportation, pipeline transportation is safe, convenient and economical, and has become an important link in the development of the energy industry. Long-distance oil and gas pipelines are characterized by high temperature, high pressure, flammability and explosion. Once a leak occurs, it will cause a major safety accident and cause huge economic losses. In recent years, some acts of destruction such as oil theft and barbaric construction have seriously threatened the safety of pipelines.

Application Background

The transportation of oil and natural gas is closely related to the national economy and people's lives. Compared with road transportation, pipeline transportation is safe, convenient and economical, and has become an important link in the development of the energy industry. Long-distance oil and gas pipelines are characterized by high temperature, high pressure, flammability and explosion. Once a leak occurs, it will cause a major safety accident and cause huge economic losses. In recent years, some acts of destruction such as oil theft and barbaric construction have seriously threatened the safety of pipelines. Pipeline failure accidents due to external disturbances, corrosion, pipe materials and construction quality threaten the national economy and the safety of people's lives and property.

Distributed fiber optic vibration monitoring system has become the focus of research due to its high sensitivity, unlimited detection points, and convenient installation and maintenance.

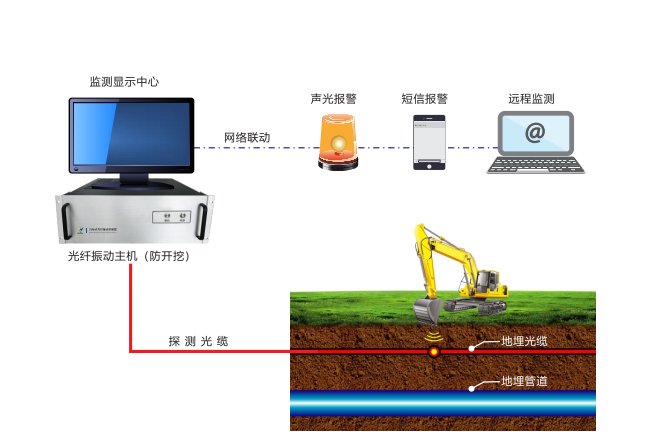

Project system schematic diagram

System Features

1) Real-time monitoring of pipeline environmental status to prevent pipeline rupture and leakage caused by human construction. When the optical fiber is touched, vibrated, or squeezed by external factors, it will cause morphological interference and change the phase of the optical signal. The system software receiver detects the phase change, detects the intensity and type of interference, processes the detected signal, determines whether the interference meets the conditions for triggering an "event", and accurately locates the interference object, thereby providing early warning of external threats that may cause damage to the oil and gas pipeline.

2) Unattended security monitoring can be achieved, and project targets can be monitored through remote desktop display and SMS alarms.

3) It can be linked with other devices, such as sound and light alarms, video cameras, etc.

HY-ZD100 Distributed Fiber Vibration System

How the vibration system works

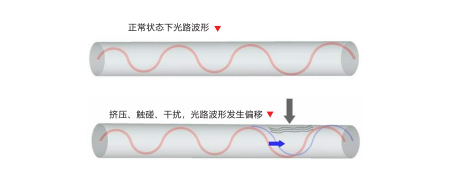

The optical fiber vibration monitoring system is based on the interference phenomenon of light.

It uses ordinary communication optical cables as sensing devices, and can detect the vibration of an optical fiber that is tens of kilometers long. The spatial sampling interval is only 1M, and the detection cycle of 50 kilometers is less than 1 second.

When an optical fiber is disturbed by external factors, the parameters in the optical interference phenomenon will change. Through high-speed signal acquisition and data processing technology, the line can be monitored through the rapid induction of optical cable touch, extrusion, and vibration, and the location of the disturbance can be accurately located and analyzed. At the same time, it can ensure normal use without being affected by external climate and harsh environment.

The path comparison of the normal state and disturbed state propagation mode of light transmitted in optical fiber is as follows:

When the optical fiber is touched, vibrated, or squeezed externally, it will cause morphological interference and change the phase of the optical signal. The system software receiver detects the phase change, detects the intensity and type of interference, processes the detected signal, determines whether the interference meets the conditions for triggering an "event", and accurately locates the interference object, thereby providing early warning of external threats such as construction, excavation, and theft that may damage the line (or adjacent cables, pipes laid in the same trench, etc.).

Product Description

The vibration monitoring system combines the principle of fiber optic interference and distributed sensing theory. Through the light in the optical fiber (drawing) laid in the defense area, the light pair touches or passes through the environmental stress induction and analysis of the carrier (such as power cables, covering soil, communication optical cables, etc.), the disturbance signal is transmitted to the system host. After signal extraction, waveform analysis and intelligent behavior judgment, different types of interference, such as mechanical operation above the optical cable, manual operation, cable damage, etc., are judged to achieve system early warning and alarm, and can be linked to video, sound and light and other equipment to truly achieve all-round, 24-hour all-round intrusion control.

This system adopts today's advanced optoelectronic technology, communication technology, microprocessor technology, digital vibration sensing technology and original design of low temperature, strong electric field, humid environment operation technology. It can monitor the pipeline line profile in real time, detect the pipeline environment profile early, prevent the pipeline from leaking due to external force damage, and minimize the loss. At the same time, it can also provide a large amount of online monitoring data, providing a reliable basis for operators to fully understand the operation of the pipeline.

Feature

1) Long measurement distance: The detection distance can reach 50km, and the intrusion point can be accurately located;

2) Continuous distributed measurement can realize simultaneous monitoring of multiple points and multiple events without affecting each other;

3) High sensitivity (alarm threshold 0-99 level). High accuracy (±5 meters);

4) Rich pattern recognition can accurately determine intrusion events;

5) Excellent electromagnetic insulation, not subject to electromagnetic interference, inherent lightning protection;

6) Intrinsically safe and reliable, optical fiber will not generate electric sparks at all, and the average power of laser pulses is very low;

7) Simple construction and convenient maintenance;

8) High tolerance for additional losses, even if there is an additional loss of 50%, it can still work normally;

9) Intelligent monitoring, easy to achieve unattended operation.

Application

Vibration monitoring for oil and gas pipeline excavation, theft, and sabotage

Vibration monitoring for power cable excavation, theft, damage, etc.

Technical Parameters

| Project | Parameter Value | unit | Remark |

| Model | HY-ZD100 | -- | |

| Fiber Type | Single Mode | -- | |

| Measuring distance | 50 | km | |

| Positioning accuracy | ±5 | m | |

| Sampling interval | 0.4 | m | |

| Alarm judgment | Vibration, contact cable | -- | |

| Scan time | 0.4 | s | |

| Dimensions (WxHxD) | 487×177×454 | mm | |

| Unit weight | 8.8 | kg | |

| Power supply | AC220V±10% | ||

| Laser radiation level | 1M | -- | |

| Device power consumption | 80 | W | |

| Fiber Optic Interface | FC/APC | -- |

(3) Distributed optical fiber pipeline leakage monitoring system for oil and gas pipelines (leakage prevention);

Oil and gas pipeline leakage will not only cause significant economic losses and serious environmental pollution, but also pose a huge threat to people's lives and property. Therefore, it is very important to monitor oil and gas pipeline leakage in real time, detect leakage in time and predict leakage risks. Existing pipeline safety monitoring methods can only passively monitor leakage points after leakage accidents occur, which cannot avoid losses.

Application Background

Leakage of oil and gas pipelines will not only cause significant economic losses and serious environmental pollution, but also pose a huge threat to people's lives and property. Therefore, it is very important to monitor oil and gas pipeline leakage in real time, detect leakage in time and predict leakage hazards. Existing pipeline safety monitoring methods can only passively monitor leakage points after leakage accidents occur, and cannot avoid losses. For example:

1) Generally, only indicators such as oil pressure and flow rate are monitored, which belongs to indirect detection;

2) The monitoring sensitivity of oil pressure, flow rate, etc. is limited, which makes it difficult to find tiny oil leakage points and the detection sensitivity is low;

3) Point detection technology is mostly used, and it is difficult to accurately locate the specific geographical location of the leakage point;

4) In terms of long-distance detection, information transmission is difficult, and additional information communication needs to be built;

5) Due to the insufficient positioning accuracy of the leakage point, it is difficult to manage the positioning information of the repair personnel in a unified manner.

Therefore, realizing early warning of destructive behaviors that threaten pipeline safety will have great social and economic benefits.

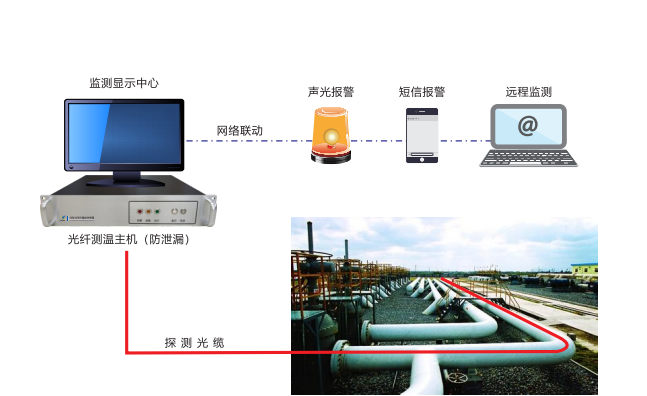

Project system schematic diagram

System Features

The distributed optical fiber temperature measurement leakage detection system is used to monitor the temperature distribution of oil and gas pipelines in real time, especially the location temperature of pipeline welding points; when the oil and gas pipeline leaks, the system can sense the temperature change nearby and alarm.

The system uses optical signals for temperature measurement and model transmission from the temperature detector to the monitoring center, realizing non-electric detection and intrinsically safe explosion-proof; the management module can also display the location and temperature information of each detector in real time, and users can intuitively understand the safety status of the equipment through this interface.

HY-DTS5100 Distributed Fiber Optic Temperature Measurement System

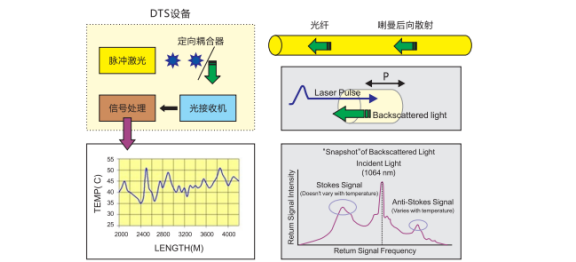

Working principle of temperature measurement system

The DTS fiber optic temperature sensor is equivalent to installing a thermometer every meter on the optical fiber of each channel. A 10-kilometer channel is equivalent to 25,000 thermometers. The host collects these temperatures and centrally calculates, stores and processes them.

The mechanism of fiber optic temperature measurement is based on the backward Raman scattering effect. The laser pulse interacts with the fiber molecules and scatters. There are many types of scattering. Among them, Raman scattering is due to the thermal vibration of the fiber molecules. It will produce a light with a longer wavelength than the light source, called Stokes light, and a light with a shorter wavelength than the light source, called Anti-Stokes light. The modulation of the external temperature of the optical fiber causes the intensity of the Anti-Stokes light in the optical fiber to change. This principle can be used to achieve distributed measurement of the temperature field along the optical fiber.

Product Description

Distributed fiber temperature sensor is referred to as DTS (Distributed temperature Sensor). Distributed fiber temperature sensor can detect the temperature distribution of an optical fiber that is several kilometers to tens of kilometers long. The spatial sampling interval is only 0.4m, and the detection cycle can reach seconds. The optical fiber itself is made of quartz and has excellent electromagnetic inertia. Therefore, DTS is an unprecedented "super temperature sensor" that is rapidly being used in fire detection, electricity, petroleum and petrochemicals and other fields.

This product system uses today's advanced optoelectronic technology, communication technology, microprocessor technology, digital temperature sensing technology and original low temperature, strong electric field, and humid environment operation technology. It can monitor the temperature in different environments separately, detect potential accidents early, and minimize losses. At the same time, it can also provide a large amount of online monitoring data, providing a reliable basis for operators to fully understand the operation of the equipment.

Feature

1) Distributed optical fiber temperature sensing equipment is used to sense temperature and position information for signal detection and signal transmission, realizing non-electric detection and intrinsically safe explosion-proof;

2) Advanced distributed optical fiber temperature sensing is used as the measurement unit. Advanced technology and high measurement accuracy;

3) The temperature measurement range of distributed temperature sensing optical cable is from -150℃ to 150℃, up to 350℃, with a wide range of applications;

4) The detector single-loop measurement method is adopted, which is simple to install and low in cost; redundant spare cores can be reserved;

5) The temperature of each partition is displayed in real time, and historical data, change curves, and average temperature changes can be displayed;

6) The system has a compact structure, simple installation, and convenient maintenance;

7) Through the software, different warning values and alarm values can be set according to actual conditions; the alarm methods are diversified, including fixed temperature alarm, temperature rise rate alarm, and temperature difference alarm.

8) Data query can be performed through the software: point-by-point query, alarm record query, interval query, historical data query, and report printing.

Application

Temperature monitoring of oil and gas pipeline leakage

Online temperature monitoring of power cables and cable tunnels

Temperature monitoring of oil depots, arsenals, dangerous goods depots, grain depots, cold storage and other warehouses

Temperature monitoring in the transportation sector

Technical Parameters

| project | Parameter Value | unit | Remark |

| model | HY-DTS5100 | -- | |

| Fiber Type | Single Mode | -- | |

| Measuring distance | 40 | km | |

| Sampling interval | 0.4 | m | |

| Positioning accuracy | ±1 | m | |

| Temperature accuracy | ±1 | °C | |

| Single channel measurement time | 5 | s | |

| Dimensions (WxHxD) | 483×88×458.8 | mm | |

| Unit weight | 7.2 | kg | |

| power supply | AC220V±10% | -- | |

| Laser radiation level | 1M | -- | |

| Temperature measurement range | -150°C~350 | °C | |

| Fiber Optic Interface | FC/APC | -- |

(4) Fiber optic perimeter security systems for important places such as oil storage depots (to prevent climbing over, crossing, intrusion and sabotage)

Currently, security products are widely used in the entire industrial chain of the energy industry. In addition to meeting the requirements of safe production in its own production processes and employee training, the petrochemical industry also needs security products to conduct real-time monitoring of its production environment in oil fields, large chemical plants, drilling platforms, chemical product storage warehouses, natural gas pipelines, etc.

Application Background

Judging from my country's current energy structure, oil and natural gas will remain the main energy supply for a considerable period of time in the future. Therefore, whether the processes of oil and natural gas extraction, processing, transportation, and use can be safe and stable in the long term will be a major issue related to the country's economic development. Human management and supervision alone cannot achieve the desired results. It is necessary to rely on scientific and technological forces to carry out all-round supervision from early warning to prevention. Therefore, security occupies a very important position in the infrastructure construction of the petrochemical industry.

Currently, security products are widely used in the entire industrial chain of the energy industry. In addition to meeting the requirements of safe production in its own production processes and employee training, the petrochemical industry also needs security products to conduct real-time monitoring of its production environment in oil fields, large chemical plants, drilling platforms, chemical product storage warehouses, natural gas pipelines, etc.

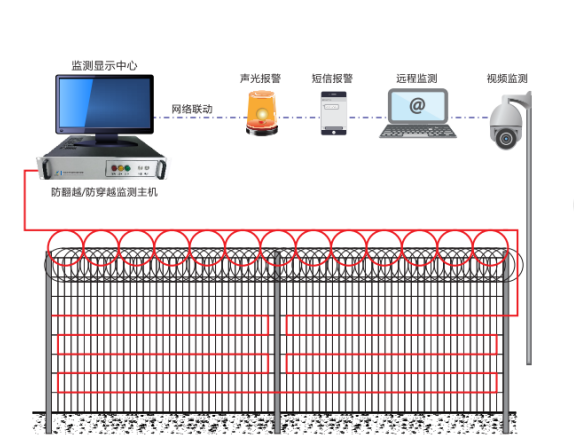

Project system schematic diagram

System Features

Fully intelligent, easy to achieve unattended operation: the system can send reports to the person in charge via SMS and the Internet when an abnormality is detected; open design facilitates data management and on-site control;

"0" missed reports: Rayleigh interferometer technology can be used to accurately locate the location of external interference; spectrum scanning technology makes it possible to identify feature intrusions and eliminate feature interference, with extremely low false alarms, ensuring that the system missed report rate is 0;

No electricity: It takes advantage of the fact that optical fiber is a passive device, without electromagnetic interference, and is more resistant to electromagnetic interference.

HY-FPS15 Distributed Fiber Perimeter System

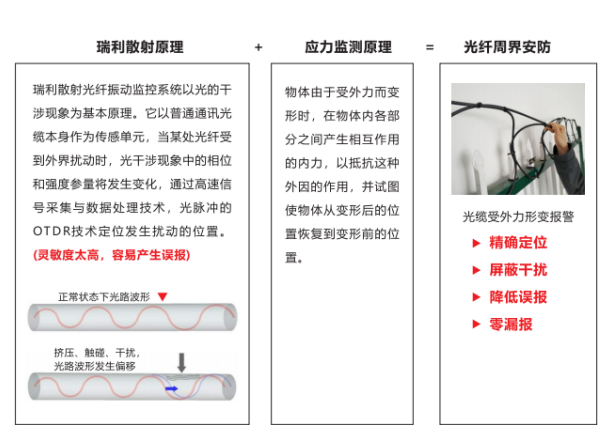

How the Perimeter System Works

Product Description

The fiber optic perimeter security system combines Rayleigh interferometry positioning technology and optical frequency domain scanning technology. It senses and analyzes the environmental stress of touching or passing through the carrier (such as walls, covering soil, fences, etc.) through the light in the optical fiber (cable) laid in the defense area, and transmits the disturbance signal to the system host. After signal extraction, waveform analysis and intelligent behavior judgment, it can judge different types of interference, such as intrusion into restricted areas, climbing over walls, crossing fences, etc., to achieve system early warning and alarm, and can link video, sound and light and other equipment to truly realize all-round, 24-hour all-round intrusion monitoring.

Feature

1) Three-dimensional protection, 360-degree perimeter security without dead angles;

2) Continuous distributed measurement, which can realize simultaneous monitoring of multiple points and multiple events without affecting each other;

3) High sensitivity and high precision (5 meters);

4) Rich pattern recognition, which can accurately determine intrusion events;

5) Excellent electromagnetic insulation, not subject to electromagnetic interference, inherent lightning protection;

6) Intrinsically safe and reliable, optical fiber will not generate electric sparks at all, and the average power of laser pulses is very low;

7) Simple construction and convenient maintenance;

8) High tolerance for additional losses, even if there is an additional loss of 50%, it can still work normally;

9) Intelligent monitoring, easy to achieve unattended operation.

Application

Perimeter security for oil depots, natural gas, power plants and other related enterprises

Perimeter security for prisons, detention centers and other high-security places

Perimeter security for various military and civil airports

Perimeter security for exhibition halls, museums, schools, villas, etc.

Perimeter security for military ammunition depots, national defense borders, etc.

Perimeter security along railways and highways

Technical Parameters

| project | Parameter Value | unit | Remark |

| model | HY-FPS15 | -- | |

| Fiber Type | Single Mode | -- | |

| Measuring distance | 15 | km | |

| Sampling interval | 0.8 | m | |

| Positioning accuracy | ±5 | m | |

| Alarm judgment | Cross, pass, destroy | -- | |

| Scan time | 0.4 | s | |

| Dimensions (WxHxD) | 484×88×454 | mm | |

| Unit weight | 6.9 | kg | |

| power supply | AC220V±10% | -- | |

| Laser radiation level | 1M | -- | |

| Device power consumption | 50 | W | |

| Fiber Optic Interface | FC/APC | -- |

0755-89217397