HY-FBG3100 series is a new generation of online temperature monitoring equipment developed and produced by ShenZhen Hoyatek Co.,Ltd. Based on the temperature sensitive characteristics of fiber gratings, it can accurately monitor the small changes in the center wavelength of the reflected light of the fiber grating temperature sensor caused by the change of ambient temperature. Realize remote, online and accurate monitoring of multiple temperature measuring points.

1. Introduction to the system

HY-FBG3100 series is a new generation of online temperature monitoring equipment developed and produced by ShenZhen Hoyatek Co.,Ltd. Based on the temperature sensitive characteristics of fiber gratings, it can accurately monitor the small changes in the center wavelength of the reflected light of the fiber grating temperature sensor caused by the change of ambient temperature. Realize remote, online and accurate monitoring of multiple temperature measuring points.

The HY-FBG3100 series requires the use of single-mode fiber optic cables and loose tube fiber optic cable structure.

Imported lasers and optical devices are used internally, optical circuits, electronic circuits and reliable control software are formed through integrated circuit modules, and are completed through strict production, assembly and product tests. The product has the advantages of high efficiency, low power consumption, high stability, convenient use and maintenance, and long life. It can be widely used in optical communication, optical sensing and other related fields; its positioning accuracy, spatial resolution, temperature accuracy and other technical parameters are all Meet the requirements of engineering applications.

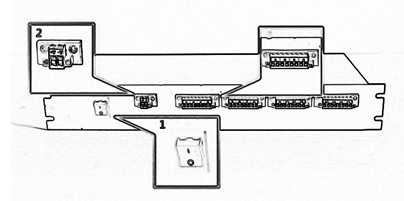

FBG temperature measurement host

2. Product features

Anti-electromagnetic interference, intrinsically safe

High sensitivity, fast response speed, long measuring distance

Corrosion resistance, aging resistance, strong environmental adaptability

With automatic gain temperature calibration function

Simple and reliable system, low maintenance cost, long service life

3. Application place

Power industry: temperature measurement in switch cabinets, transformers, generators, transmission lines and cables, and ring network cabinets;

Petrochemical industry: temperature measurement of oil in oil storage tanks;

Metallurgical industry: temperature measurement of objects and liquids in flammable and explosive environments

Four, technical standards

The equipment provided by our company is designed, manufactured, inspected and installed in accordance with the following standards and regulations. Ensure that the standard used is the latest version. If the content of these standards is inconsistent, the terms of the highest standard shall be implemented or the standards agreed upon by both parties shall be implemented. The following standards and specifications are part of compliance, but not all of them.

GB/T 2423.1-2008 | Environmental testing of electrical and electronic products |

GB 4943-2001 | Information technology equipment safety |

GB/T 17626.6-1998 | Electromagnetic compatibility test and measurement technology Radio frequency field induced conducted disturbance immunity |

GB/T 17626.11-2008 | Electromagnetic compatibility test and measurement technology Voltage sag, short-term interruption and voltage change immunity test |

GB/T 21197-2007 | Linear optical fiber temperature sensing fire detector |

Five, system equipment

5.1 FBG temperature measurement host technical indicators

Wavelength range | 1525~1565(nm) |

Number of measurement channels | 1~16 |

Detection range | -40~-15(dB) |

Temperature measurement range | -30℃~120℃ |

Temperature measurement accuracy | ±0.5℃ |

Temperature display resolution | 0.1℃ |

scanning frequency | 5Hz (single channel) |

Temperature display method | Data+chart |

The band of the sensor | C |

size | Standard 19 inch 1U chassis |

weight | 4 KG |

Fiber type | Ordinary single-mode fiber |

Interface Type | FC/APC |

Communication interface | RS232、Ethernet |

Operating platform | Linux, Windows |

power supply | AC220V±10% |

Operating temperature | -10℃~50℃ |

Storage temperature | -40℃~70℃ |

Relative humidity | ≤95%RH(40±2℃) |

5.2 Fiber Bragg Grating Temperature Sensor

It adopts metal-free packaging structure such as ceramics and quartz, which has high insulation and intrinsic safety. It is used for accurate temperature measurement in high pressure occasions such as tunnel fire fighting, oil pipe temperature measurement, and temperature compensation environment.

characteristic

l Simple operation

l High sensitivity

l No metal

Performance

parameter | unit | Numerical value | Remark |

Center wavelength | nm | 1510-1590 | |

Measuring range | ℃ | -30 ℃~120 ℃ | customizable |

Resolution | ℃ | 0.1 | |

Temperature measurement accuracy | ℃ | ±0.5 | |

size | mm | 3*3*28 | |

Connector | -- | FC/APC or welding | Others can be customized |

Pigtail | Teflon Loose Tube |

5.3 Installation of the sensor

Before preparing to install the sensor, you must first read the following installation instructions and fully understand it. Because the sensor is a precision device, any small installation defect will cause the sensor's test error or no sensor damage, so you must be careful when installing it.

Installation method:

The installation of the temperature sensor is relatively simple. During installation and use, the sensor can be fixed on the surface of the measured body.

Physical quantity calculation method:

y = 16935841702.734 x3 - 29483227.552 x2 + 156637.695 x + 20。

Among them, "y" is the temperature, and "x" is the value of (λ-λ20°C)/λ20°C.

"Λ" is the wavelength value at ambient temperature, that is, the test wavelength value.

"Λ20℃" is the wavelength value provided on the test sheet.

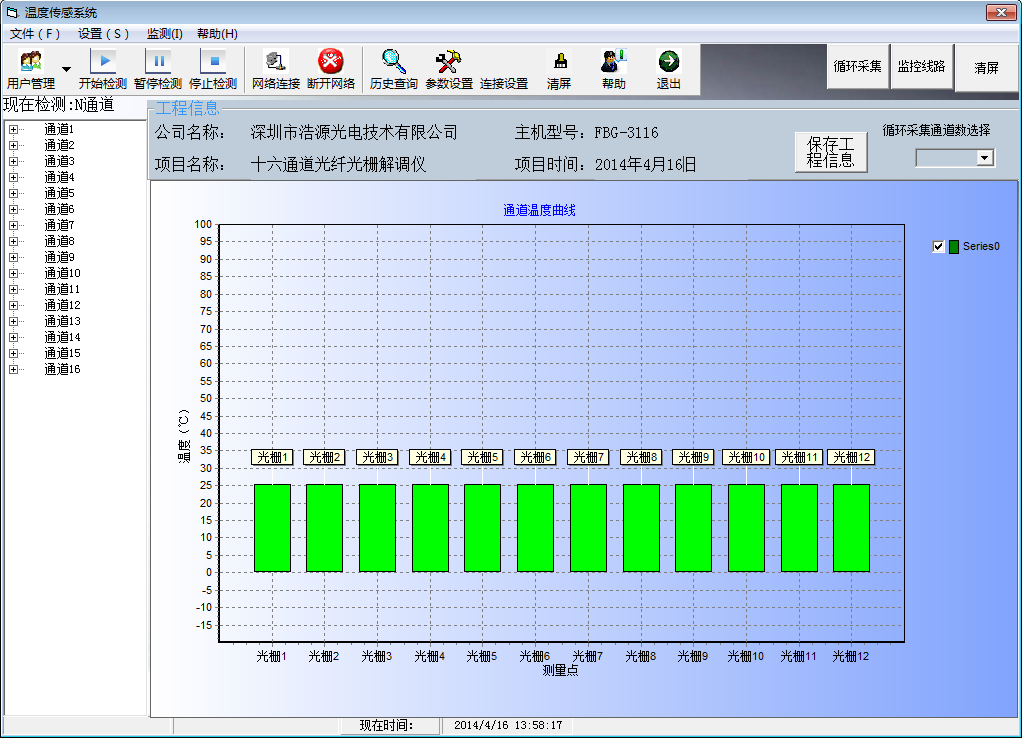

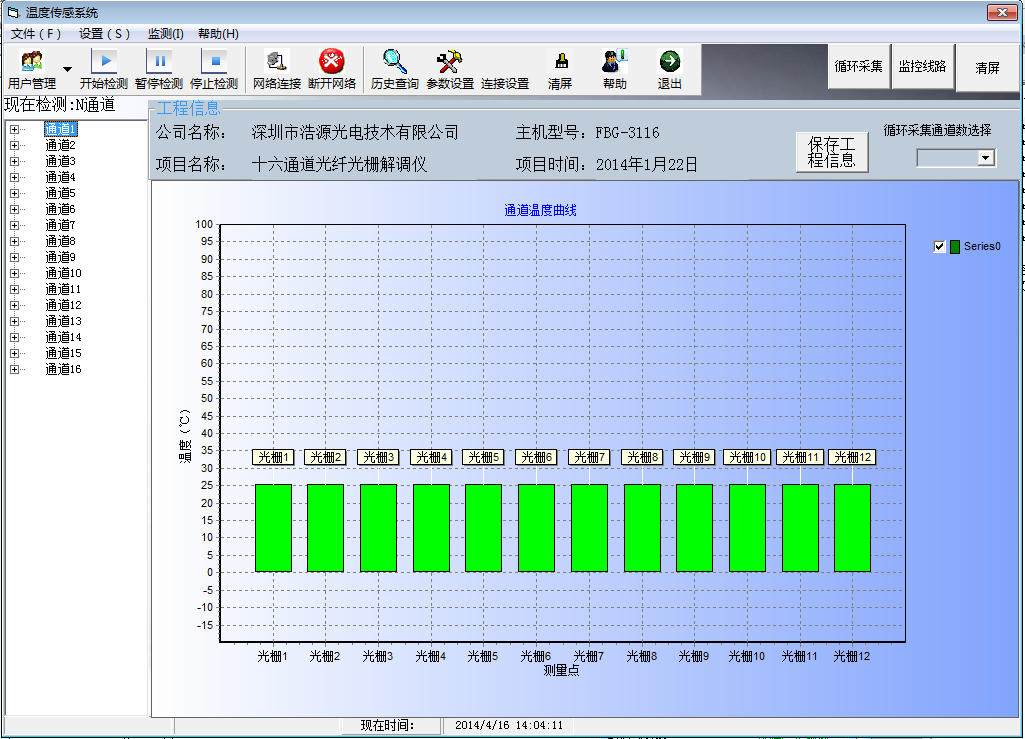

Six, FBG discrete optical fiber temperature monitoring software interface

6.1 Software main interface

Ø Toolbar: User management: Administrator authority can add, modify, and delete users.

Ø Connect to the network: when the network is not connected, click this button to connect to the network, if the connection is successful, the icon will turn from gray to bright

Ø Start detection: After the network is connected, click "start detection", the icon will turn from bright to gray, and the upper computer will automatically obtain the data of the lower computer and display it in real time.

Ø Pause detection: After starting the detection, you can click "Pause Detection" to pause the detection.

Ø Stop detection: After starting the detection, you can stop the detection.

Ø Disconnect from network: In the case of network connection, you can click "Disconnect Network" to disconnect. When the network is connected, click this button, the network will be disconnected, and the "Network Connection" button will turn from bright to gray.

Ø Historical query: Click this button to pop up the historical data query window, you can query the data information of each raster point of each channel.

Ø Parameter setting: Click this button, a parameter setting window will pop up, and the height of each grating point of 16 channels can be adjusted separately.

Set the low temperature alarm and early warning value.

Ø Clear screen: Click to clear the histogram of the main interface icon.

Ø Exit: Click to exit the program.

Ø Cyclic acquisition: cyclic acquisition of channel data. The number of acquisition channels can be customized.

Ø Monitoring line: Click to enter the monitoring line interface, and the temperature information of 192 grating points will be displayed in real time.

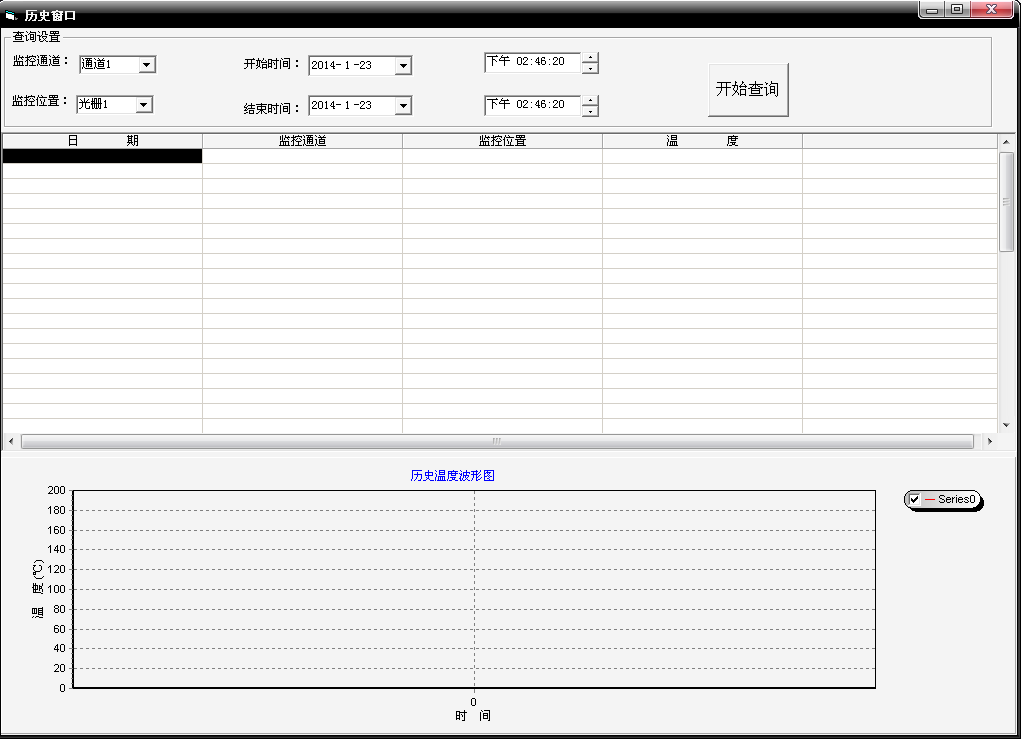

6.2 History query interface

The data information of each channel and each raster point can be queried according to the conditions.

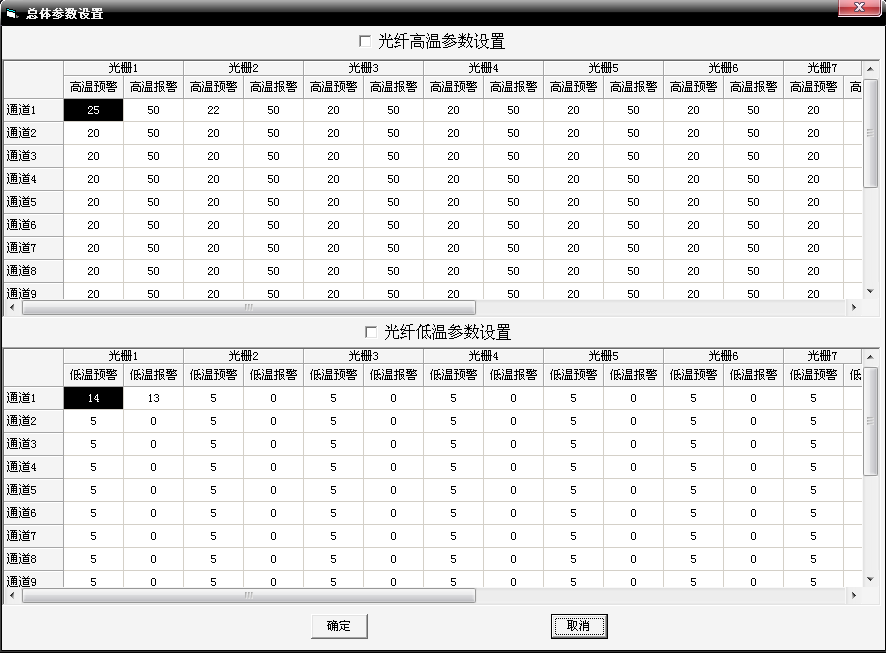

6.3 Parameter setting

The high and low temperature alarm and early warning value of each grating point can be set separately. After setting, click "OK".

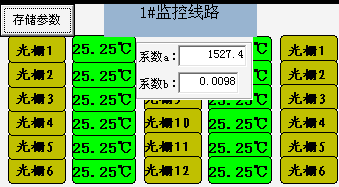

6.4 Monitoring circuit

The temperature information of 192 grating points is displayed in real time. The temperature is within the pre-warning temperature range, and the display temperature frame shows green; when the temperature exceeds the pre-warning value, it turns yellow, and when the temperature exceeds the warning value it turns red.

Click on the temperature value, and a button for setting parameters for changing the raster will pop up. After entering the parameters of the corresponding raster, click the "Save Parameters" button. The parameters of each grating point can be set according to the actual situation.

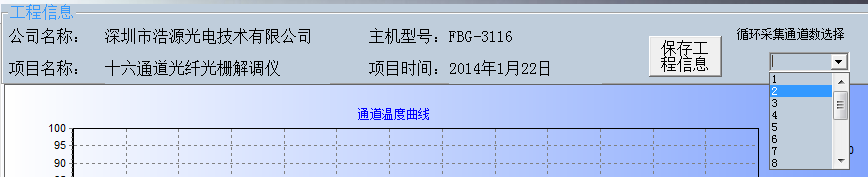

6.5 Engineering Information

You can edit and modify the project information by yourself. After re-editing, click the "Save Project Information" button to start again, and the main interface will display the updated information.

6.6 Selection of the number of cyclic acquisition channels

Click the drop-down box, select the number of cyclic acquisition channels, and click the "Cyclic Acquisition" button on the toolbar, and the system will cyclically collect the data of the set number of channels.

Click the channel number in the list to select a channel to monitor, and the main interface displays the histogram of the temperature information of the raster point of the channel.

6.7 Analysis of common problems

1. No temperature data:

1. Check whether the network is connected:

Click the "Network Connection" button of the host computer, if the network is connected, the button turns from gray to bright. If the button is always gray, it means that the network is not connected.

Analysis and solution: Ping the IP of the device on the PC to see if it can be pinged. Select the computer "start"--"Run"--"cmd--"ping 192.168.1.220. If the ping fails, check whether the IP of the PC is in the same network segment as the device, and check whether the network cable is well connected.

2. If the network connection is normal, check whether the external optical fiber link of the device is connected: wipe the connector with alcohol and re-test.

2. Each link has only part of the temperature data or a certain temperature data is particularly abnormal:

1. Check whether each grating parameter setting corresponds

2. Check whether the link grating connection is intact

7. Relay, photo-acoustic alarm device

Relay:

Communication interface | RS232 (2 pcs) |

Number of relay channels | 16/32, can be customized |

power supply | DC 12V |

Sound and light alarm device:

Used in conjunction with the relay control board, it can be displayed according to the current operating status of the system.

normal | Green light | silent |

Early warning | Yellow light | Warning tone |

Call the police | red light | Alarm tone |

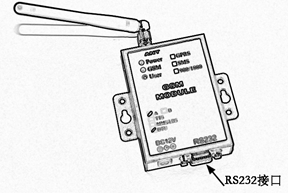

8. Wireless signal transmitter (optional)

Communication interface | RS232 |

Wireless mode | GSM (Mobile/Connectivity) |

power supply | DC 5V |

9. Recorder and display (optional)

Desktop computer host: WIN7 operating system, 1TB hard disk; 4G memory; 4 core CPU;

LG 21.5-inch LED display;

Serial port, 10/100M network port each 1PCS;

Mouse and keyboard set

10. Standard cabinet and installation accessories (optional)

² Height: 42U-6U

² Depth: 960mm/800mm/600mm/450mm

² Material: A3 cold rolled steel plate

² Frame: 2.0mm thick reinforced steel, bearing 700kg, other parts 1.5mm

² Process: cleaning treatment, phosphating anti-corrosion treatment, electrostatic spraying treatment according to the national standard IP23 level

0755-89217387